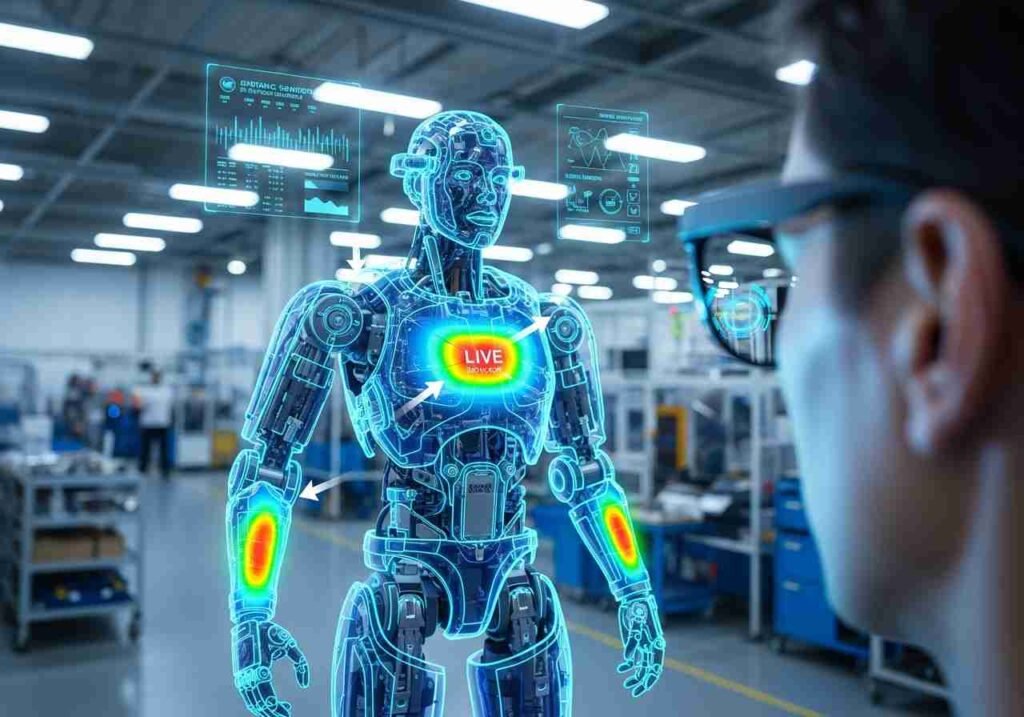

suppose that a technician is looking at a broken robot. Then, all at once, schematics and live data are suspended in the air before them. This is not science fiction. The influence of AI Robotics and augmented reality coming together is the potent one that is currently occurring. This hybrid is producing a super human work force. Are we ready for it?

What Is a Digital Twin? Beyond the Hype

Forget static blueprints. A digital twin is a virtual living breathing model. It is related to its physical counterpart through sensors and the use of AI. It is thus real time updated. This renders an ideal copy of digital cloning.

Imagine a live-streaming heartbeat of a machine. All vibrations, temperature variations and performance indicators are reflected. It gives a historic perspective of the system.

An engineer with Siemens explains “that a digital twin is the interface between the physically real world and the digital one.”

This is a technology that is blowing up. MarketsandMarkets forecasts the market to be up to 110.1 billion by 2028. Smart factories are the cause of this growth.

AR Revolution: X-Ray Vision of Technicians

Introduce now that digital twin to the field of view of a worker. This is facilitated by Augmented Reality glasses such as Microsoft HoloLens. They superimpose vital information with the physical world. Technicians have a peephole x-ray view of complicated equipment.

They watch cartoon repair manuals. They see live thermal information. Technicians are able to emphasize a particular part of a machine with a multitude of parts. This makes the cognitive load much lesser. Errors will be reduced.

According to one BMW service technician, “the AR overlay provided me with the precise bolt. I didn’t even have to think.”

Efficiency soars. Indicatively, for example, a study conducted by Boeing established that AR guidance led to a reduction of 25 percent of the time spent in wiring production. Errors by workers were also reduced to a substantial degree.

The Remote Pro: Your Pro in the Pocket

What in case the team at the site gets stalled? Remote expertise comes in at this point. With AR, a local technician can show a specialist in the other part of the world his or her live point-of-view. The specialist may then make digital marks into the visual field of the technician.

“See this valve? Turn it slowly.” The instructions are direct and crystal clear. This is a solution to the enormous skills shortage in industry. One specialist is capable of serving dozens of locations at a time.

Firms such as Librestream claim to reduce the time taken to solve a problem by more than 40 percent. The cost of travel in order to get specialists has also decreased dramatically. It is a massive victory in terms of operational budgets.

Training in the Risk-Free Universe

What is the way to train somebody on a million-dollar Humanoid Robot? You do not allow them to feel it. They practice on its ideal digital image in VR instead. The trainees are able to practice, commit disastrous errors and learn. None with the slightest mark on the material property.

They develop muscle memory and profound knowledge. This develops unbelievable confidence. PwC discovered that VR-trained workers studied 4 times quicker than in the classrooms. They were also more sure by 275%.

A Real-Life example: The Omniverse by NVIDIA

So, we will take a practical example. The NVIDIA platform known as Omniverse is an advancement. It enables companies to create physically realistic full-factory digital twins. Indicatively, BMW is developing a full virtual copy of a full factory.

New layouts of production can be simulated by engineers. They are able to test interactions of robots. They are able to streamline operations to the fullest in the digital realm. This eliminates expensive mistakes in the actual factory. The savings are monumental.

The Human Factor: Not Replacement, but Augmentation

One of the fears is the fact that this technology is replacing people. In reality, it augments them. This is to eliminate the boring activities. This will enable the human experts to concentrate on problem-solving and innovation.

Automating the routine is a motto of one of the lead designers at Magic Leap: automating the intellect. The machine handles data. Context and creativity is handled by the human. This is the partnership of the future of work.

The Future is Embodied: The Place of Humanoid Robots?

This base forms the basis of the future of Robotics. Consider a time when a general-purpose Humanoid Robot worker can be found on the construction site. What are we going to say to them? The necessary connection will be AR interfaces and digital twins.

We are going to view their work and sensor information on the real world. Their training will be in simulation. They will be monitored in a smooth manner. The job that is occurring today is this preparation of that future.

The Final Decision: Develop an Augmented-Ready Culture

It is not only the hardware of robots and the intelligence of AI. The human interface represents the actual change. Businesses that invest solely in machines are lacking the big picture.

An augmented-ready culture is the most worth investing in. We need to equip our employees with such inhuman capabilities. The coming generation is the one that connects the most between human and machine.